Hastelloy B-3 Plate

Hastelloy B3 is a nickel-based high-temperature alloy, mainly composed of nickel, molybdenum, cobalt and other elements, of which the nickel content is about 65%. This alloy material is optimized on the basis of Hastelloy B2. By improving the thermal stability of the material, it significantly enhances the corrosion resistance, while also effectively improving the hot forming and cold forming performance. In recent years, Hastelloy B3 has been increasingly used in the production and manufacturing of chemical equipment. Hastelloy B3 material has many unique properties. Its high elongation provides favorable conditions for cold forming operations. Compared to austenitic stainless steel, Hastelloy B3 material is harder and therefore requires greater pressure during cold forming or step forming processes.

Products

Products DETAILS

Hastelloy B-3 Plate

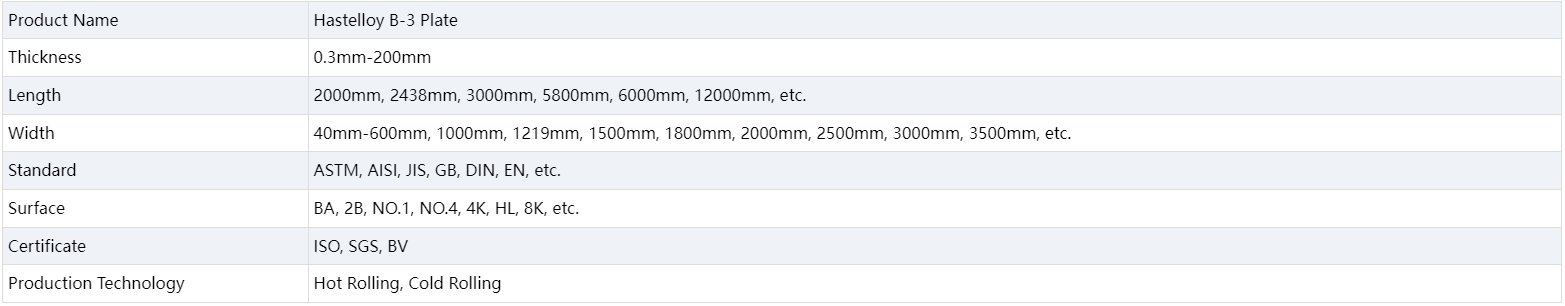

Product Parameters

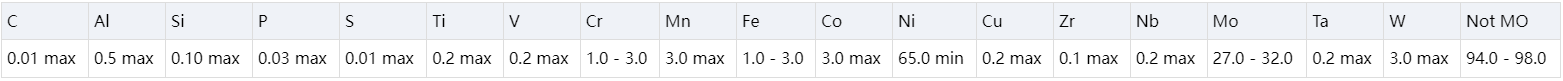

Chemical Composition

Chemical Composition

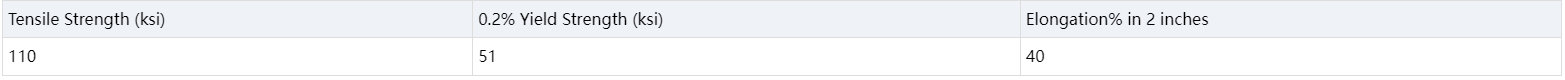

Mechanical Properties

Mechanical Properties

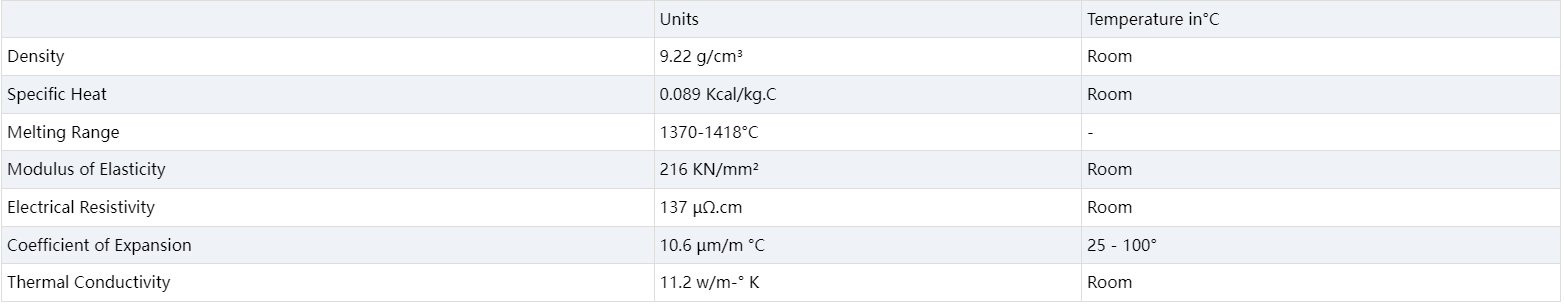

Physical Performance

Physical Performance

Scope of Application

B- 3 is used in chemical processes, vacuum furnaces, mechanical parts in reduced pressure environments, etc.