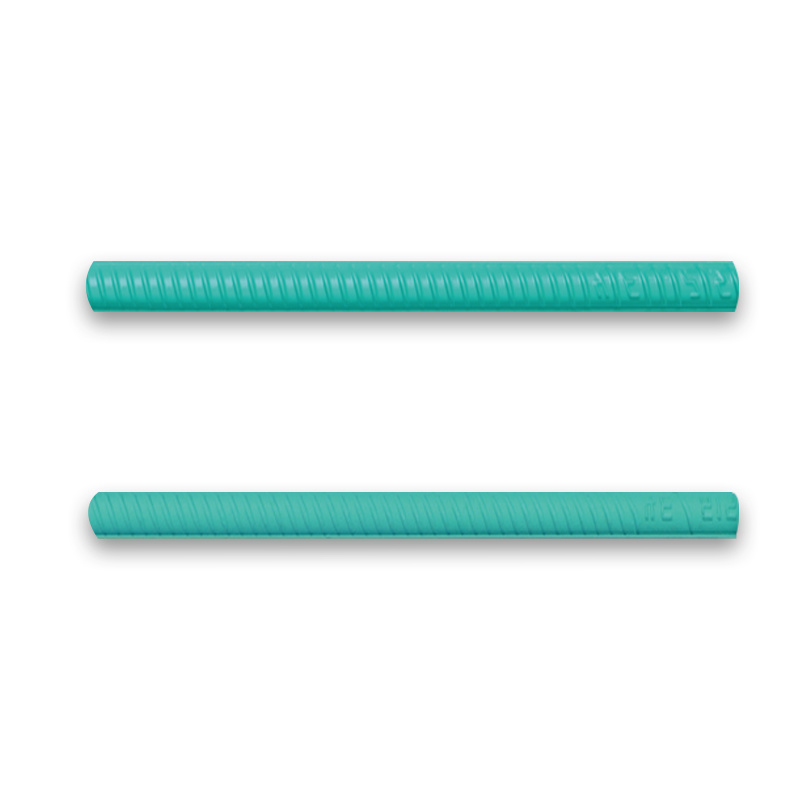

Epoxy Resin Coated Steel Bar

China's epoxy coated steel bars adopt national standards GB/T 25826-2010 and Ministry of Housing and Construction standard JG/T 502-2016 (replacing JG 3042-1997). American standards are ASTM A775/A775M and ASTM A934/A934M, and British standard is BS ISO 14654. The whole life cycle analysis shows that the comprehensive cost of epoxy coated steel bar is very low. Epoxy coated reinforced concrete structures have a longer life than ordinary carbon steel concrete structures. The coating of the bar has anti-permeability, so it can delay the corrosion medium (such as water, oxygen, chloride, etc.) contact with the steel, so that its corrosion resistance life is greatly extended.

Products

Products DETAILS

Epoxy Resin Coated Steel Bar

Product Parameters

Grade of Base Material Reinforcement

HRB400, HRB400E, HRB500 HPB300 (Hot Rolled Round Steel Bar)

Coating Technology

EN/DIN/JIS/ASTM/BS/ASME/AISI, etc.

Coating Standard

GB/T 25826-2010, JG/T502-2016

Conventional Diameter

10/12/14/16/18/20/22/25/28/30/32/36/38/40/50mm

Custom Diameter

6mm-50mm

Standard Length

6m/9m/12m (Length can be customized)

Use

Anti-floating anchors, bridges, railways, seaports, nuclear power, sewage tanks, petrochemical and chemical projects with corrosion resistance requirements

Chemical Composition of Base Metal

Carbon

Silicon

Manganese

Sulphur

Phosphorus

0.25%

0.80%

1.6%

0.045%

0.045%

Mechanical Properties of Base Metal

Chinese Rebar Code

Yield Strength (Mpa)

Tensile Strength (Mpa)

Carbon Content

HRB400, HRBF400, HRB400E, HRBF400E

400

540

≤ 0.25

HRB500, HRBF500, HRB500E, HRBF500E

500

630

≤ 0.25

HRB600

600

730

≤ 0.28

Scope of Application

Widely used in houses, bridges, roads, especially railways and other civil engineering.