Propeller Shaft - Marine Forgings

Products

Products DETAILS

Propeller Shaft - Marine Forgings

Propeller Shaft - Marine Forgings Description

A propeller shaft, also known as a drive shaft, transmits torque and rotation from a vehicle's transmission to its wheels or other mechanical components. It's a vital part of automotive and machinery systems, allowing power to be efficiently transferred while accommodating changes in distance and alignment between components.

Propeller shaft is a fundamental component responsible for transferring the torque from the gearbox to the rear axle or differential. It is also called the Cardan shaft or Drive shaft. Although widely used in cars, this vital mechanism also finds application in boats and airplanes. Constructed as a hollow, tube-like structure, the propeller shaft combines universal and slip spline joints.

In traditional automobile designs, with the rear end engine, this shaft allows the propulsion of the rear wheels. This effectively transmits power from one end of the vehicle to the other. On the contrary, in modern-day front wheeled cars, a shorter shaft serves the purpose. In any case, the propeller shaft remains a critical link in the chain of power transmission within the automotive, marine, and aviation domains.

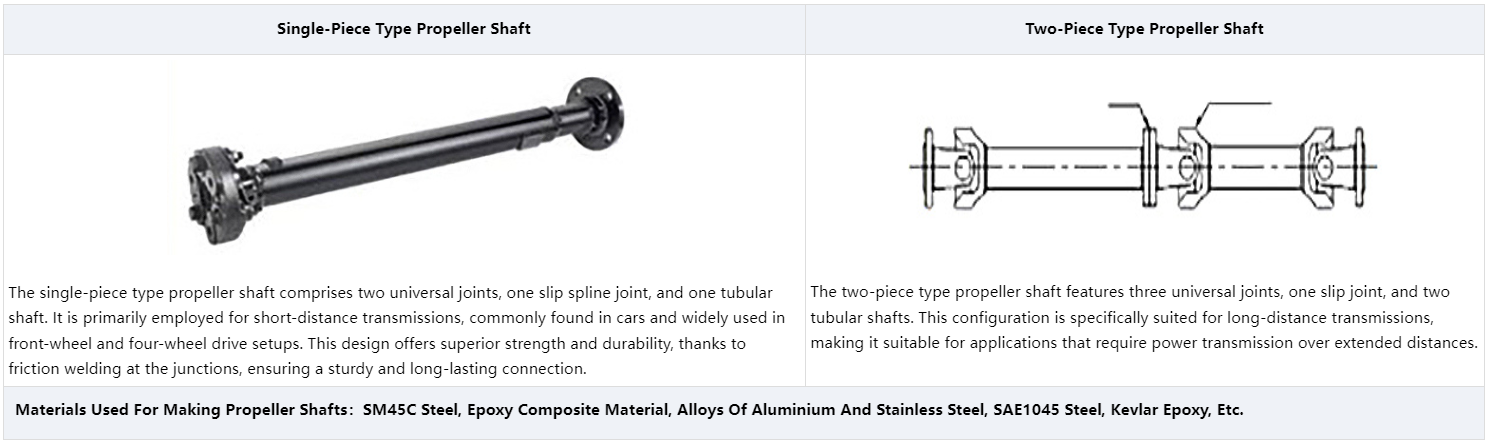

Types of Propeller Shafts

Advantages of Propeller Shafts

● Low or No Power Losses: Propeller shafts facilitate efficient power transmission, resulting in minimal or negligible power losses during the process, optimising overall performance.

● Lightweight Tubular Structure: The tubular design of the propeller shaft contributes to its reduced weight, positively impacting the vehicle's overall weight distribution and fuel efficiency.

● Simple Construction: The propeller shaft's design is relatively straightforward, making it easier to manufacture and maintain, ensuring cost-effectiveness.

● Safe Power Transmission: With its sturdy construction and reliable materials, the propeller shaft ensures secure and safe power transfer from the engine to the wheels, enhancing driving stability.

● Low Noise at High Torques: The well-engineered propeller shaft minimises noise generation, even under high torque conditions, providing a smoother and quieter driving experience.

● Durability: Built from robust materials like high-quality steel, the propeller shaft exhibits exceptional durability and resilience, withstanding challenging operating conditions.

● Minimal Maintenance: Due to its sturdy construction and efficient power transmission, the propeller shaft generally requires minimal maintenance, reducing downtime and associated costs.