DX51D/SGCC Galvanized Sheet

DX51D galvanized sheet is divided into cast zinc alloy and deformed zinc alloy. Commonly used cast zinc alloy is zinc aluminum copper magnesium alloy, its casting process performance is good, cooling speed has less effect on mechanical properties, more used in the manufacture of mechanical parts, toys, decorations, household appliances and so on. Commonly used deformation zinc alloys are zinc aluminum alloy and zinc copper alloy. The former contains 4% to 15% aluminum, in order to improve the strength and hardness of the alloy, but also add a small amount of copper, magnesium and other alloying elements. Its high strength can replace some brass or duralumin manufacturing precision forgings. The latter contains 0.7% to 1.5% copper, copper can increase alloy strength and impact toughness, and reduce plasticity.

Products

Products DETAILS

DX51D/SGCC Galvanized Sheet

Scope of Application

Galvanizing products are widely used in industry, agriculture, animal husbandry and fishery, energy, transportation, chemical industry, light industry, home appliances, construction, communications, national defense and other fields.

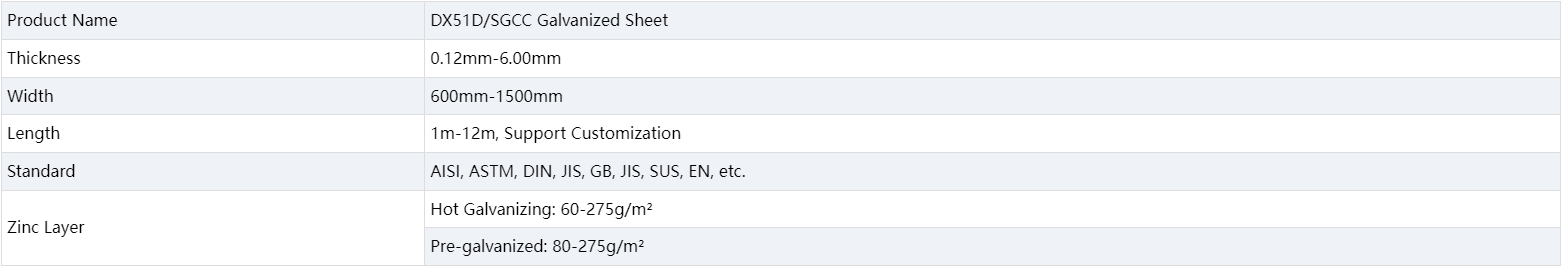

Product Parameters

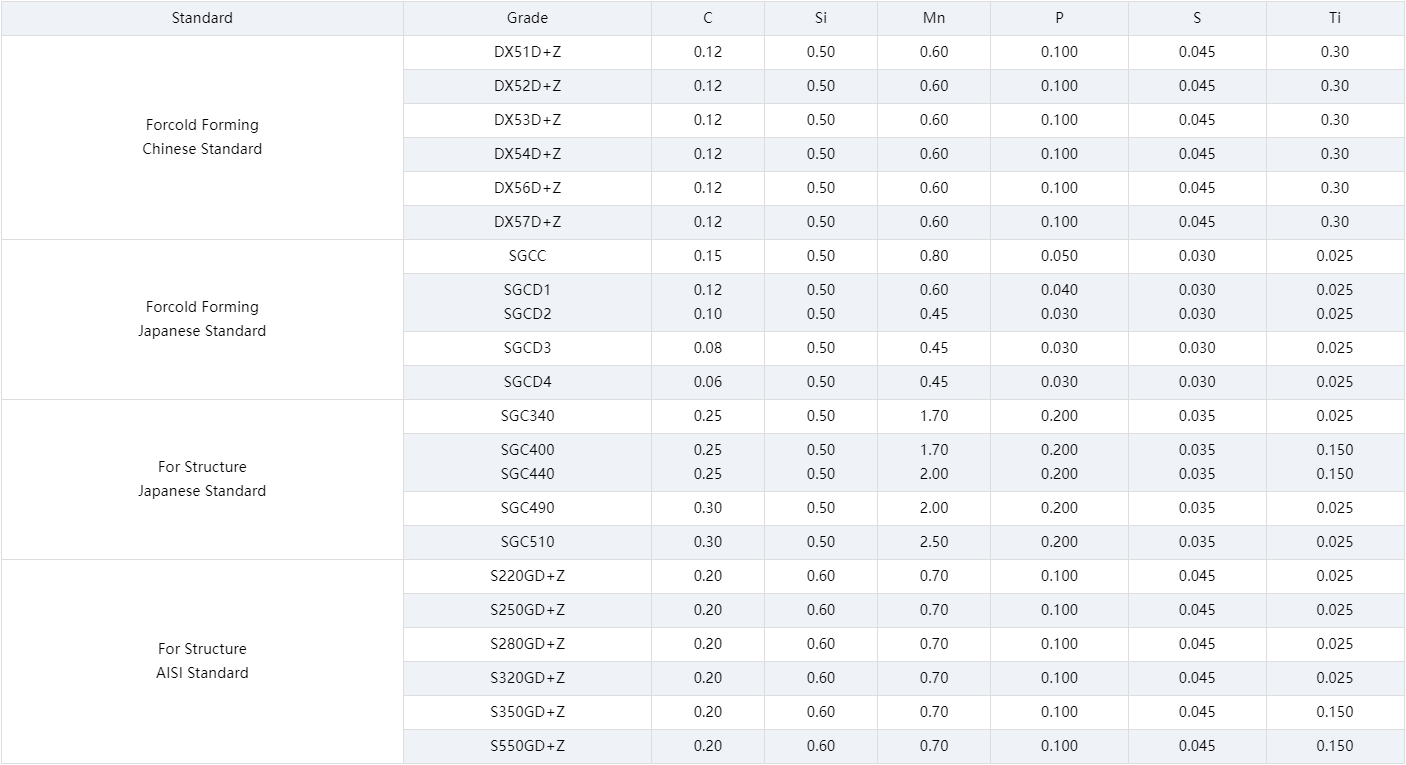

Chemical Composition

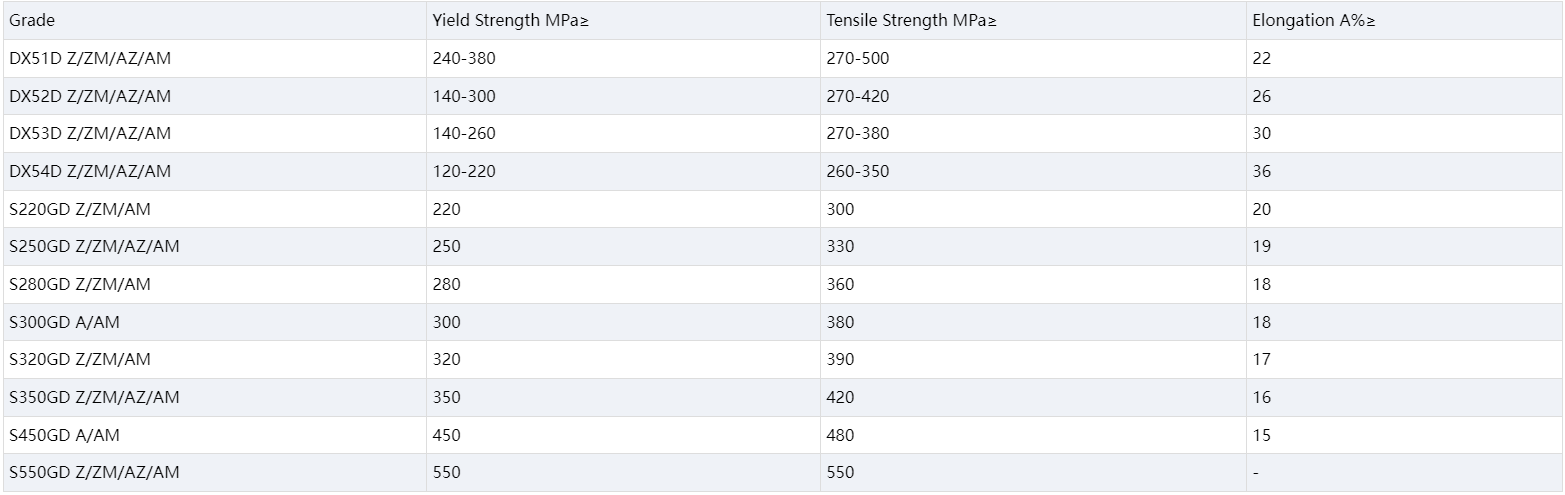

Mechanical Properties

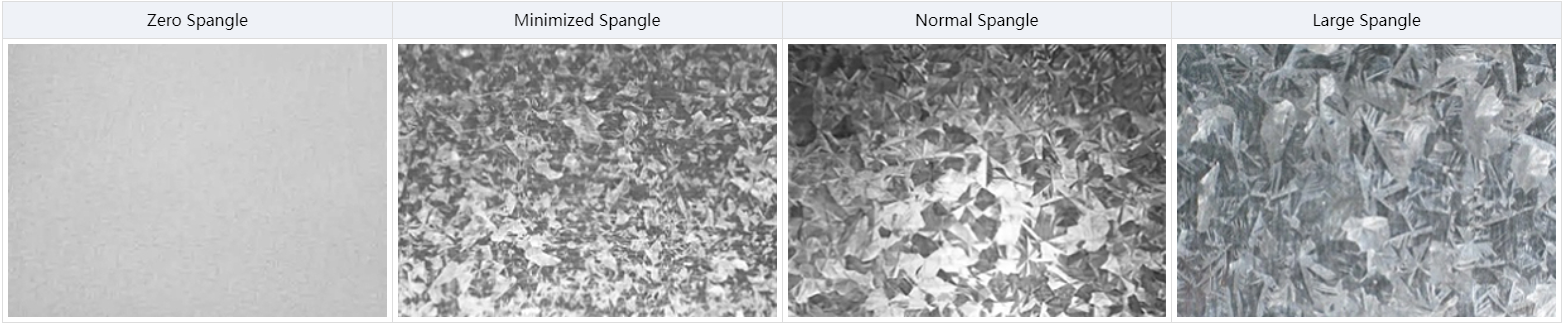

Galvanized Surface Selection

Galvanized Surface Selection