Hot Dip Galvalume Steel Coil

Hot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Compared with other metal protection methods, the hot-dip galvanizing process has advantages in the protection characteristics of the combination of physical barrier and electrochemical protection of the coating, the bonding strength of the coating and the substrate, the compactness, durability, maintenance-free and economy of the coating, and its adaptability to the shape and size of the product.

Products

Products DETAILS

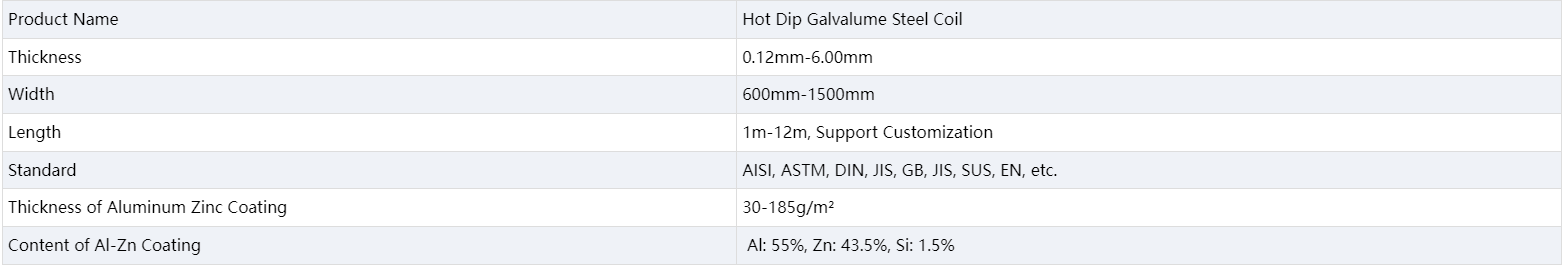

Hot Dip Galvalume Steel Coil

Product Parameters

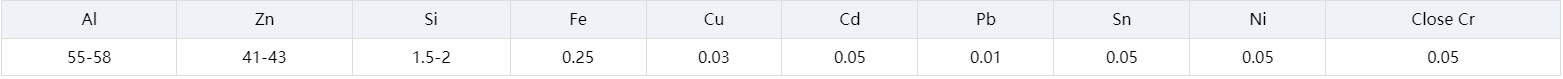

Chemical Composition

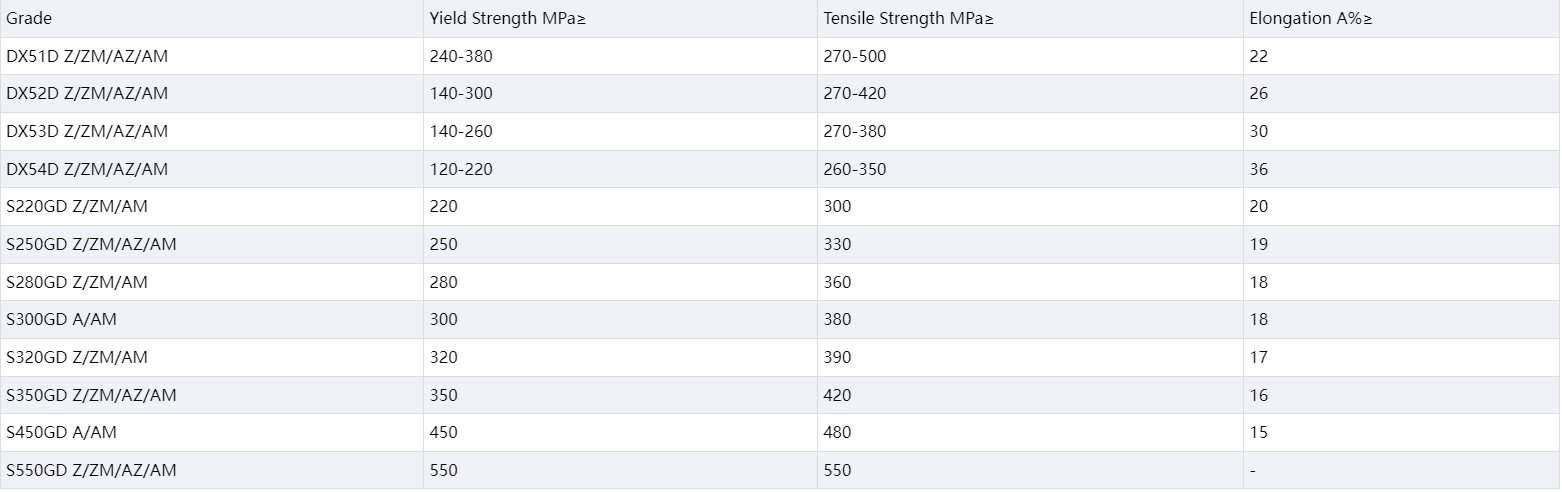

Mechanical Properties

Mechanical Properties

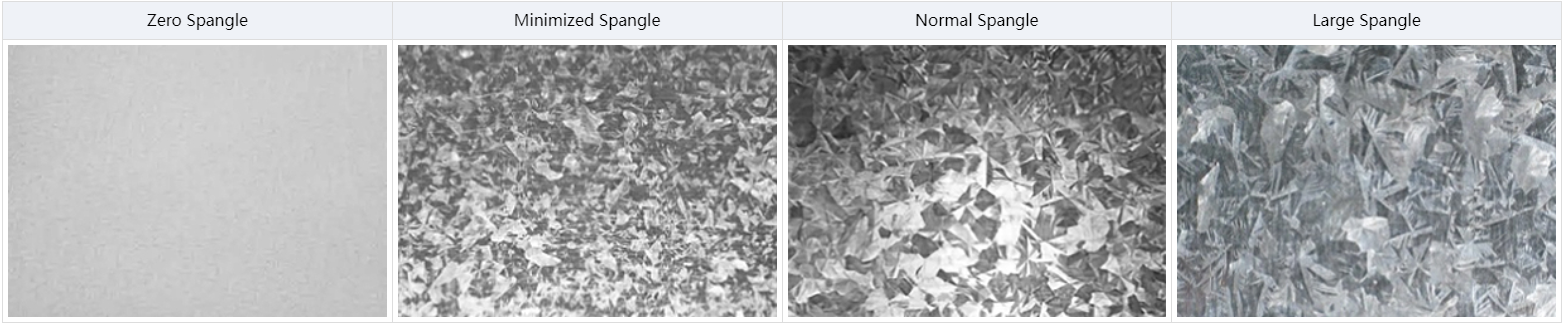

Galvanized Surface Selection

Galvanized Surface Selection

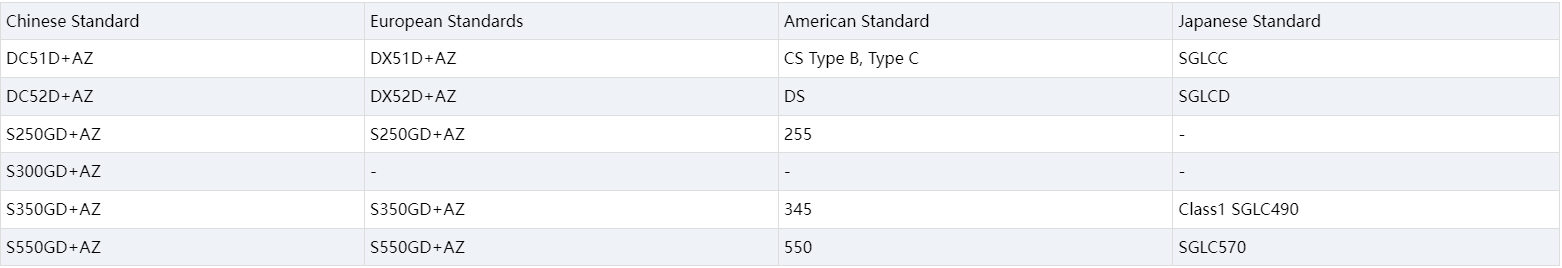

Material Comparison