1050 Aluminum Coil

Aluminum 1050 alloy is composed of 99.5% pure aluminum, and tiny amounts of copper, manganese, magnesium and other elements for smelting. The density of aluminum 1050 alloy is about 2.7g/cm, which is lighter than steel, helping to reduce product weight and increase energy efficiency. Besides, aluminum 1050 alloy has high strength and good fatigue resistance to improve the service life of 1050 aluminum coil. Aluminum 1050 alloy also has excellent electrical and thermal conductivity, which leads to better heat dissipation and energy transmission of the product. Moreover, 1050 aluminum coils can resist the corrosion of acid, alkali, salt and other corrosive media to a certain extent. Lastly, aluminum 1050 alloy is easy to process, and can be made into various profiles, plates, pipes and so on by rolling, extrusion, stretching and other methods.

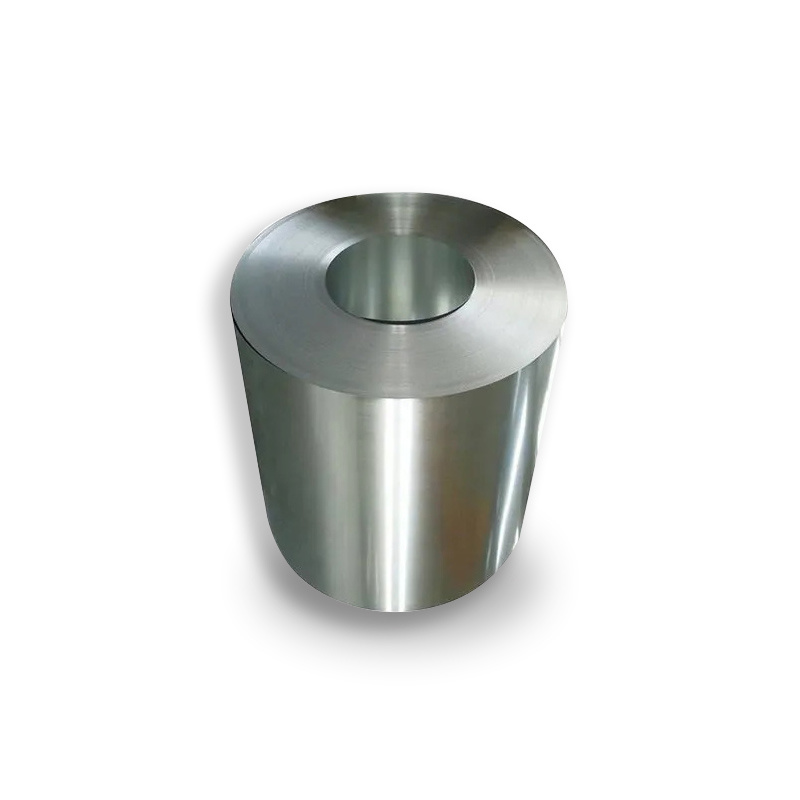

Products

Products DETAILS

1050 Aluminum Coil

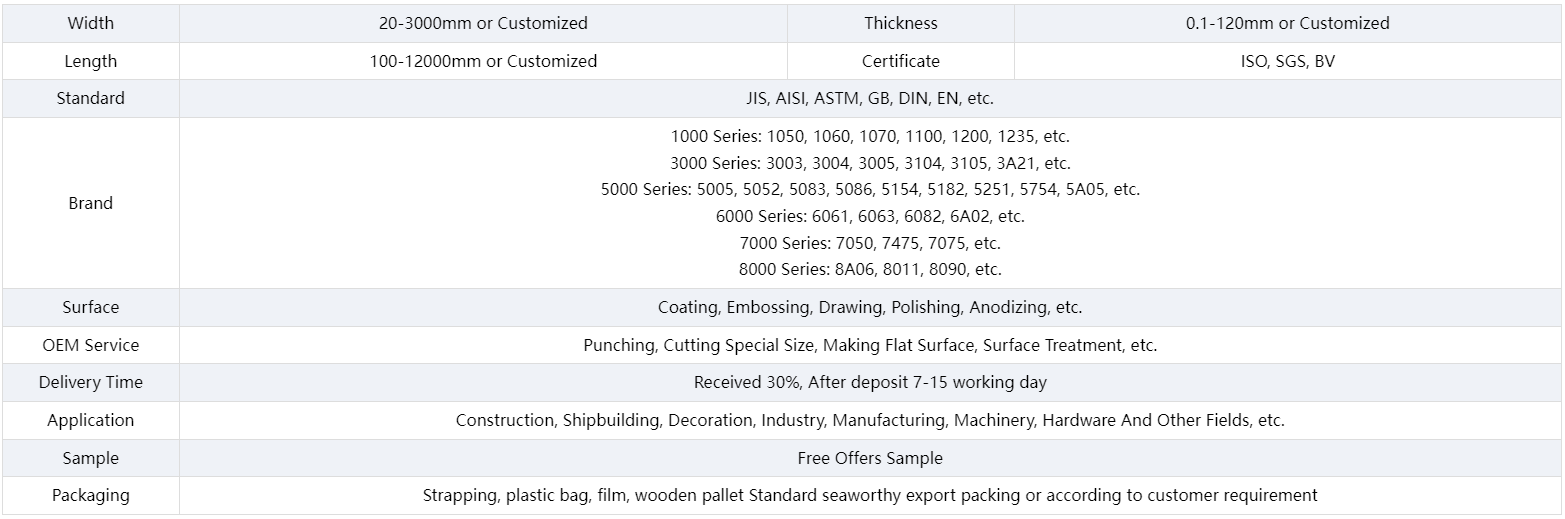

Product Parameters

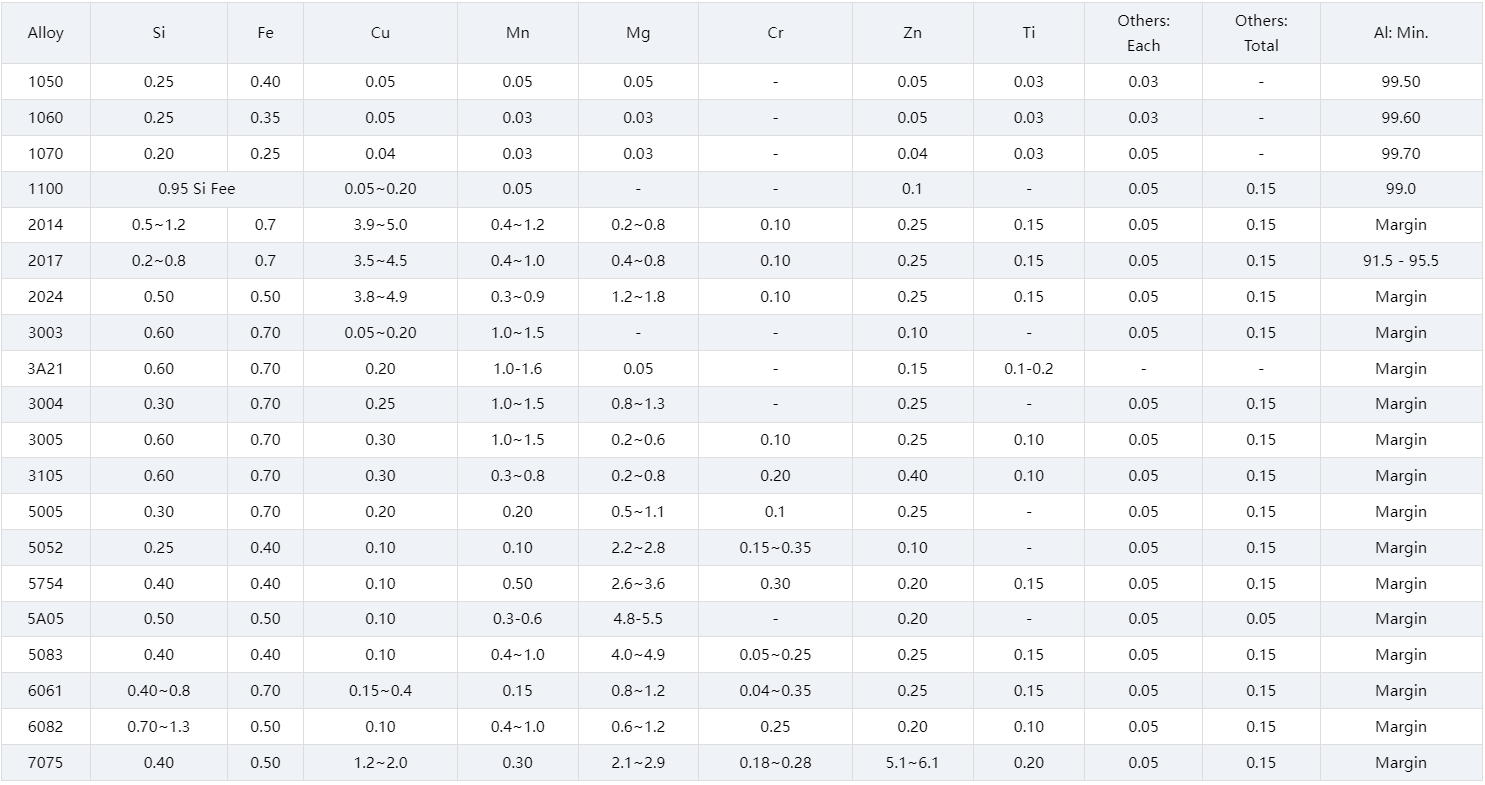

Chemical Composition

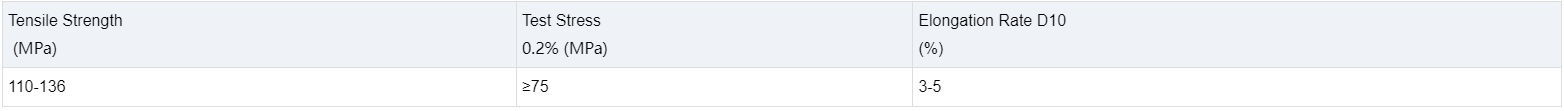

Physical Performance

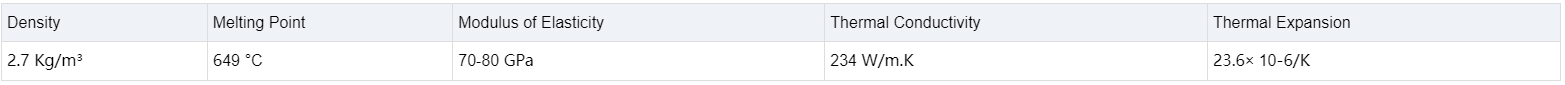

Physical Performance

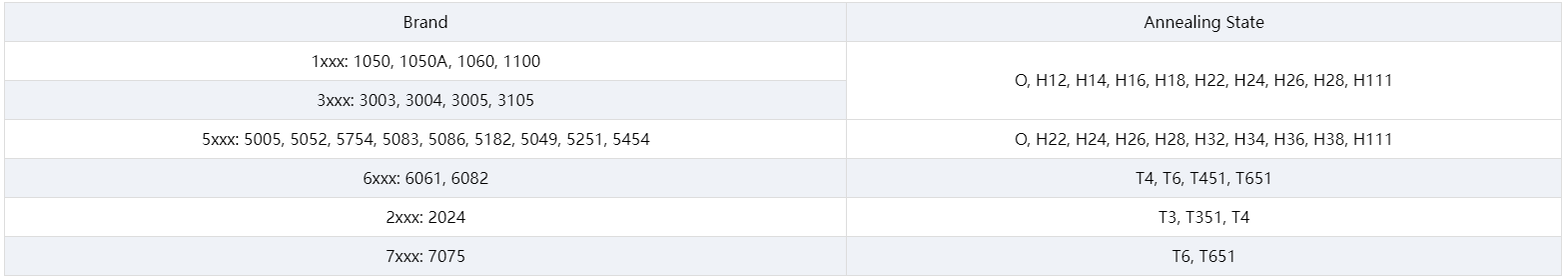

Annealing State

Annealing State

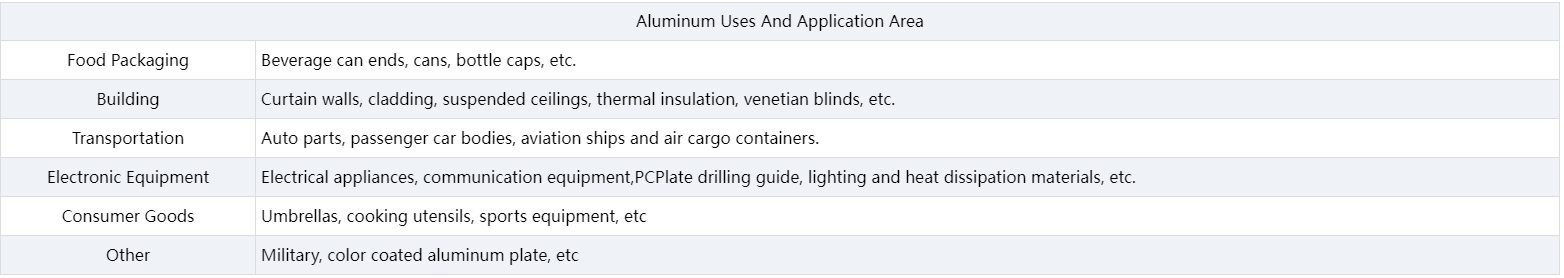

Scope of Application

Scope of Application